Discovery of ethylene polymerization reaction with the formation of polyethylene became for humanity the same epoch-making event as the emergence of glass making or the onset of the oil refining era. Quite quickly, a practical application for new thermoplastics was found – they began to make T-shirt bags, D cut bags, loop bags from HDPE, LDPE, MDPE. Convenient, safe and practical packaging has taken root so much in production, trade and in everyday life that soon environmentalists sounded the alarm – they began to colorfully paint an apocalyptic picture of garbage “Chomolungma”, into which the surface of our planet began to turn. Then chemists got to work and invented biodegradable packages.

It would seem that with their appearance the problem was solved. After all, ecopackages in nature decompose in a couple of years, and are even recyclable (at least biopackages made with the addition of D2W oxodegradation additives by Symphony Environmental Technologies plc. However, the controversy around this topic does not subside. In order to dot the i's, we decided to understand the issue in detail and impartially.

Humanity produces a huge amount of garbage. According to the State Statistics Service of Ukraine, every inhabitant of our country sends 271 kg of waste to the landfill per year (German – 626 kg, so we “litter” no more than European countries). However, the entire Western Europe is successfully recycling its own garbage (and Sweden even buys up from its neighbors – it does not have enough of its own). And our landfills have already accumulated about 13 billion tons of waste, which “in terms of Chomolungma” exceeds the size of the highest mountain in the world (8.848 km). If we recalculate the size of the Ukrainian “garbage Everest” in cubic meters and “pile” a mountain from it with a base of 20 km in diameter, then it will reach a height of 10 km.

1. Store at landfills

Emerging problems:

accumulation of bioinert mass with toxic compounds that enter the water;

accumulation of chemicals with pathogenic microflora in the soil;

formation of “landfill gases” with a greenhouse effect.

2. Burn

Emerging problems:

air pollution and deterioration of already unfavorable environmental situation;

3. Recycle

Emerging problems:

high energy consumption;

lack of waste sorting culture in Ukraine, infrastructural and mental ill-preparedness of people for civilized waste collection.

Therefore, we need to develop production of eco-packages. And such technologies not only already exist, but are actively used. In particular, you can buy ecopackages right now from us. Interested? Then let's study them out to understand what are biodegradable packages, what are their benefits and disadvantages.

Biopackages are packaging that is quickly biodegradable in nature, but with the same performance properties in other respects as the usual T-shirt bags and D cut bags. Biodegradation is decomposition of complex substances into simple components. Simply speaking, it is decomposition of a product into small particles under the influence of moisture, atmospheric ozone, ultraviolet radiation, temperature, microorganisms, fungi, etc.

biodamage or destruction;

fragmentation;

assimilation.

Ordinary polyethylene is a rare long-liver. Under natural conditions, it decomposes for centuries. However, there are already technologies that significantly speed up packaging decomposition process.

Today on an industrial scale, practically or theoretically, it is possible to produce:

1. Hydrodegradable packaging made of bioplastics: corn and potato starch, cellulose, proteins (soy, casein, gluten), castor oil (PA 410), GM corn, etc. However, the production of many of them is too expensive and energy-intensive, and they only decompose in conditions created for composting. Therefore, experts believe that this is not a way out.

“Growing huge amounts of agricultural crops in order to turn them into disposable items is a completely irrational use of the planet's resources,” says one of the leading Russian experts on environmental policy A. Ivannikov.

2. Oxo-biodegradable packaging. This is made of polyethylene with additives (modifiers of thermoplastics): D2W by Symphony Environmental Technologies plc (Great Britain), ADDITECH ® ОC “Technocom” (Ukraine), etc. Biodegradable polymers are rapidly destroyed in natural conditions with the formation of harmless simple substances (water, carbon dioxide, methane, biomass), therefore do not harm nature and do not worsen the state of the environment. Oxo biodegradable packages can be ordered by clicking on the link here.

Production of synthetic biodegradable thermoplastics seemed fantastical until relatively recently. However, thanks to the onset of modern technology, the task has become quite solvable.

Scientists have found out that polyethylene should be modified in such a way that it degrades in 2 stages:

Destruction of crystalline macromolecular structure under the influence of chemical and physical environmental factors (heat, light, water, ozone, sun, oxygen).

Assimilation of residues by biological microorganisms (fungi, bacteria, insects) with subsequent degradation to carbon dioxide, water and other safe components.

Conventional polymers have large molecular sizes and strong bonds in the crystal structure. To speed up the process of their decomposition, unstable composite polymers with additives that contribute to degradation of thermoplastic must be used for production of polyethylene.

Polymeric material can be made biologically degradable by introducing a filler into its composition, which, due to substituents in the side group, will weaken the crystal structure and accelerate the effect of chemical, physical and biological factors that contribute to degradation.

However, it is necessary to use a filler that does not change the performance properties of polyethylene. That is, the material for production of eco-packages will remain the same strong, safe, non-toxic, it will not fall into pieces in the warehouse or in the hands of the buyer.

using a composite of a mixture of synthetic and natural polymers (starch, chitin, chitosan);

synthesis of a composite polymer with biodegradable components that act as a catalyst for decomposition of the base polymer;

introduction of molecules with functional groups subject to photodegradation (dithiocarbonates, vinyl ketone monomers, copolymers of ethylene with carbon monoxide, etc.) into the macrochain.

The latter method has proven itself better than the other ones. In particular, the use of D2W biodegradable additive (organic dithiocarbonate) manufactured by oxodegradation additives (UK), has become widespread. This is what we use in the production of eco-packages for MPAK products.

Production process of biodegradable packages is similar to traditional technology. Extruder produces plastic mass, from which the sleeve is then blown out. Further, polyethylene can be laminated, printed using flexoprinting method, and used to make eco-packaging from it.

Degradation process of polyethylene with D2W additive takes place due to sequential oxidation and biodegradation.

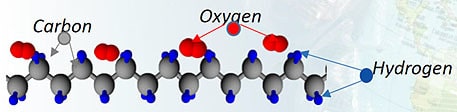

Figure 1

D2W prodegradant destroys carbon bonds and activates breakdown of long molecular chains of polyethylene. During the abiotic phase, molecules with short chains and low molecular weight are formed. Polyethylene loses its strength, becomes brittle, falls into pieces.

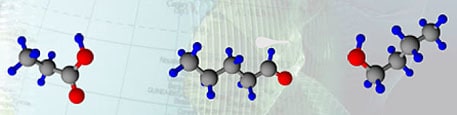

Figure 2

The resulting free radicals form hydroperoxide under the influence of oxygen, polyethylene becomes hydrophilic – it absorbs water and swells.

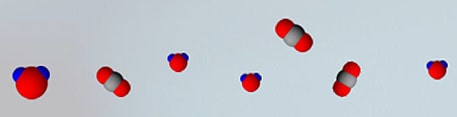

Figure 3

The resulting hydroperoxides begin to biodegrade naturally. They become available to microorganisms, which process them to form water, carbon and biomass (ketones, aldehydes, compound ethers, etc.).

Swedish professor Ignacy Jakubowicz, a leading specialist at the RISE research institute, head of the research and development department of chemistry of materials and surfaces, author of more than 30 scientific papers, describes the action of D2W as follows:

“The process of oxo-biodegradation of polyethylene is not only a fragmentation, but is an entire change in the structure of thermoplastic from a high molecular weight polymer to monomeric and oligomeric fragments and from hydrocarbon molecules to oxygen-containing molecules which can be bioassimilated”.

Introduction of new technologies can really save us from garbage collapse and preserve the environment.

One of the most interesting know-how is edible packages. A variety of packaging made of edible materials can be safely called their ancestors: Japanese disposable dishes made of pressed rice flour, wafer cups familiar to all of us from childhood. And not so long ago, in Germany, they began to produce jars and boxes made of gelatin, starch, natural cellulose, in which they sell desserts, vegetable and meat dishes, soups, noodles, cereals, etc.

Other countries stay abreast. For example, in Brazil you can buy pizza in a package made from... tomato puree. It can be safely sent to microwave and eaten with your favorite Margherita or Pepperoni.

The Brazilian restaurant chain Bob's invites customers to eat a hamburger along with paper.

Lavazza offers its customers an edible coffee cup. Its outer layer is made from Italian Amaretinni biscuits according to a special reciope, and the inner layer consists of icing sugar that slowly sweewtens the espresso and prevents the drink from absorbing.

In fact, you won't surprise anyone with edible film – it has been produced in the world for more than half a century. However, there is such a huge potential in this interesting topic that work is in full swing on it.

A few years ago, a group of students and teachers of one of the universities in Ukraine created edible bags from molten polysaccharide that taste like ordinary noodles. Creative inventors with their startups took part in the University Startup World Cup and won the Sustainability awards.

They presented quite strong bags (withstand up to 4 kg) that can be placed in microwave, sent to freezer, eaten on their own or offered to one of their tailed or horned pets.

So do not be surprised if a cafe abroad offers you to eat your own... hamburger pack or pizza plate. Along with biodegradable packages, this alternative waste solution is getting more and more popular.

The slogan in protection of nature can solve the problem of the garbage apocalypse: “Buy bio package – save the planet”. And we are sure that in the near future it will definitely become the motto of the new global eco-flash mob.